The making of a dream shop...

The 32' x 50' building is a barn, featuring a gambrel roof and post-and-beam interior details. The central space is the main shop (25' x 32'), organized around the machinery, with an 11' ceiling. The area under the shed roof on the left has an overhead door which opens to a materials storage area and a utility closet behind it for the air compressor and central dust collection equipment. On the opposite side of the shop area, facing north, is a drawing studio (10' x 12'), a workbench and tool area (14' x 12') open to the main shop, and a small glass studio (7' x 12').

Architectural drawings, draft upon draft, consumed the calendar from December 2012 up through March 2013.

We began clearing the site, back behind and south of the garage in January. Eugene and his crew removed trees and cleared brush.

Danny and Don rolled in: removed the stumps, corraled the logs -Red Oak and Post Oak. See Photo Gallery

February featured Ted and his portable sawmill arrive to process logs felled in the clearing -- sawed up some 1300 board feet of oak lumber, including resawn pine beams that were remnants of the original house construction. Lotsa dust. See Photo Gallery

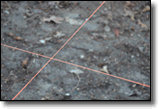

March arrives and the building is layed out on the site, it's time to break ground, dig down and start rising out of the ground...foundation footings. Doc and his crew join in with Don R moving the earth.

See Photo Gallery

Moving right along - concrete foundation walls are built atop the footings and the big hole in the ground is filled. We had enough of a break to get this in before the rains came.

See Photo Gallery

We have enjoyed cool temperatures and rainfall the last two weeks of March, though it slowed construction down. Finishing the preparations under the slab are the next step. Electrical conduit is installed by Richard and Nathan, topped off by compacted gravel. Inspector Pearl is on duty... canine quality control. See Photo Gallery

A small break in the rain and prep work prior to pouring the concrete slab is now in place. A plastic vapor barrier and steel rebar grid for extra support is added under key locations under the slab. See Photo Gallery

A two-day window of good weather and the concrete slab is poured. Half of the building was finished each day plus a short approach to the garage door. See Photo Gallery

Gordon's team from Bear Creek Nursery in Eureka Springs installed 15 bamboo plants to provide a screen between the shop and the neighbors. See Photo Gallery

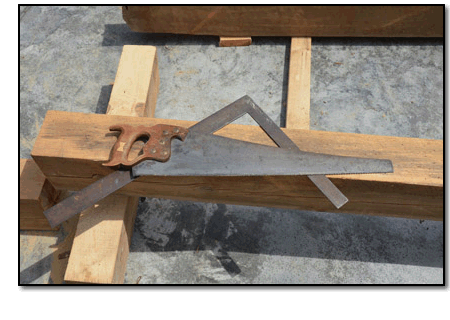

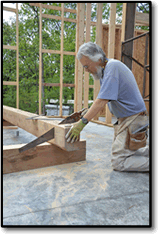

May brought us a surprise snowfall and the rising of the shop walls. Carpenters, Ricky and Ted, joined in the project to begin the wood frame construction. Milled timbers from the land and heritage family tools from 3 generations back were brought into the mix. Past, present, and future united. See the wall framing action Photo Gallery.

What's next? Ceilings of course... The main shop area features an 11' high ceiling with the remainder of the shop at 9'. There will be an attic floor over the center of the building for overhead storage. Photo Gallery.

Roof framing: What's a barn without a gambrel-style roof to top it off? Higher pitch roof allows for storage area above and room for mechanical systems overhead. Photo Gallery.

As June heats up, time to put a skin on the barn: metal siding on 3 sides (cedar board and batten on the front-later) and metal on the roof. But first, skylights and roof edges are finished. Photo Gallery.

Exterior trim work on the barn is completed and the shift to finishing the inside begins...

Road to the shop

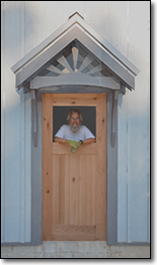

Road to the shop Future shop front door

Future shop front door Front Door Installed

Front Door Installed Front Door Canopy

Front Door Canopy

Measure Twice, Cut Once

Measure Twice, Cut Once